Student start-up develops biodegradable masks

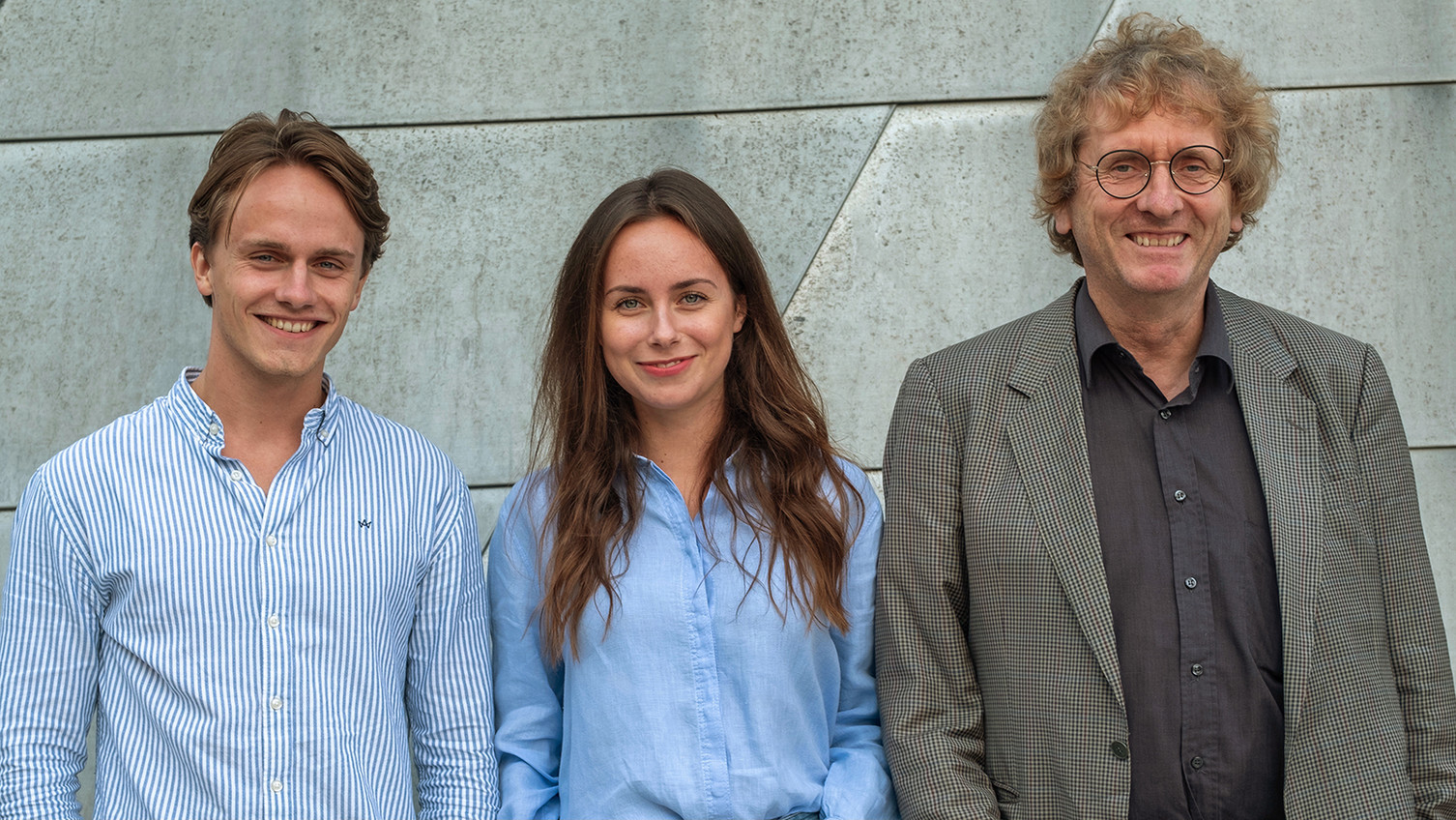

2021-02-15 Lea Lensky and Victor Büchner not only wanted to produce healthier protection, but also solve an environmental problem. They founded the company "Holy Shit." and are now presenting their first product, the VivaMask.

Already at the beginning of the pandemic, Lea Lensky and Victor Büchner noticed the increasing waste caused by masks. Medical masks are usually made of polypropylene, a material that is difficult to degrade. The two students have long been part of the team of Prof. Dr. Michael Braungart, Professor of Ecodesign. The environmental chemist founded the Cradle to Cradle principle: the basis is a product design in which abrasion and wear products, as well as those that can enter biological systems, are returned to nature as nutrients. Technical nutrients should be able to be reused "forever". Products are designed according to these principles from the very beginning - including the VivaMask. During development, Lea Lensky and Victor Büchner were able to draw on tried and tested materials: The biodegradable material Lyocell has already been used in the fashion industry for some time. It consists of cellulose extracted from beech or eucalyptus trees. "This requires about ten times less water and six times less land than cotton cultivation," explains Victor Büchner. The elastic ear straps of the masks, which are also biodegradable, are a special feature. The 22-year-old is studying International Business Administration & Entrepreneurship at Leuphana College. Lea Lensky is taking two Bachelor's programmes at the same time, Business Administration and Cultural Studies: "We founded the company not just to talk about sustainability, but to actually change something."

Their community mask is not only intended to benefit the environment, but also the wearers: According to the Hamburg Environmental Institute - headed by Prof. Dr. Michael Braungart - the disposable masks examined there sometimes contain "considerable amounts of pollutants" such as "volatile organic hydrocarbons and formaldehyde". In addition, respirable microplastic fibres can be inhaled, especially when worn, which can then accumulate in the human organism. "With the start-up, we want to call on the industry to finally produce healthy masks. Many masks are made in China. There is hardly any environmental or health debate there," says Michael Braungart. The material of the masks is not only healthy, but also washable, completely biodegradable in nature and is supposed to inhibit the growth of bacteria.

Since Lea Lensky and Victor Büchner founded the company in the middle of the lockdown, all steps of the project were carried out digitally: "We had the fabric samples sent to us, all meetings were held via video call," they both report. After less than half a year, their product VivaMask was launched on the market and can be ordered online. The two founders also have an answer to the current obligation to wear a medical mask. The mouth and nose cover contains a compartment for an FFP2 insert: "Now we are working flat out to get our masks certified.