Business models and processes

How do companies minimize their carbon footprint? Where can resources be saved and costs minimized? And how can we work together to shape a sustainable transformation of the economy? Questions like these are on the minds of the companies we work with as the Leuphana Innovation Community Sustainable Production. Because only with holistic approaches that rethink both the corporate value proposition and operational processes can sustainable potential be systematically tapped.

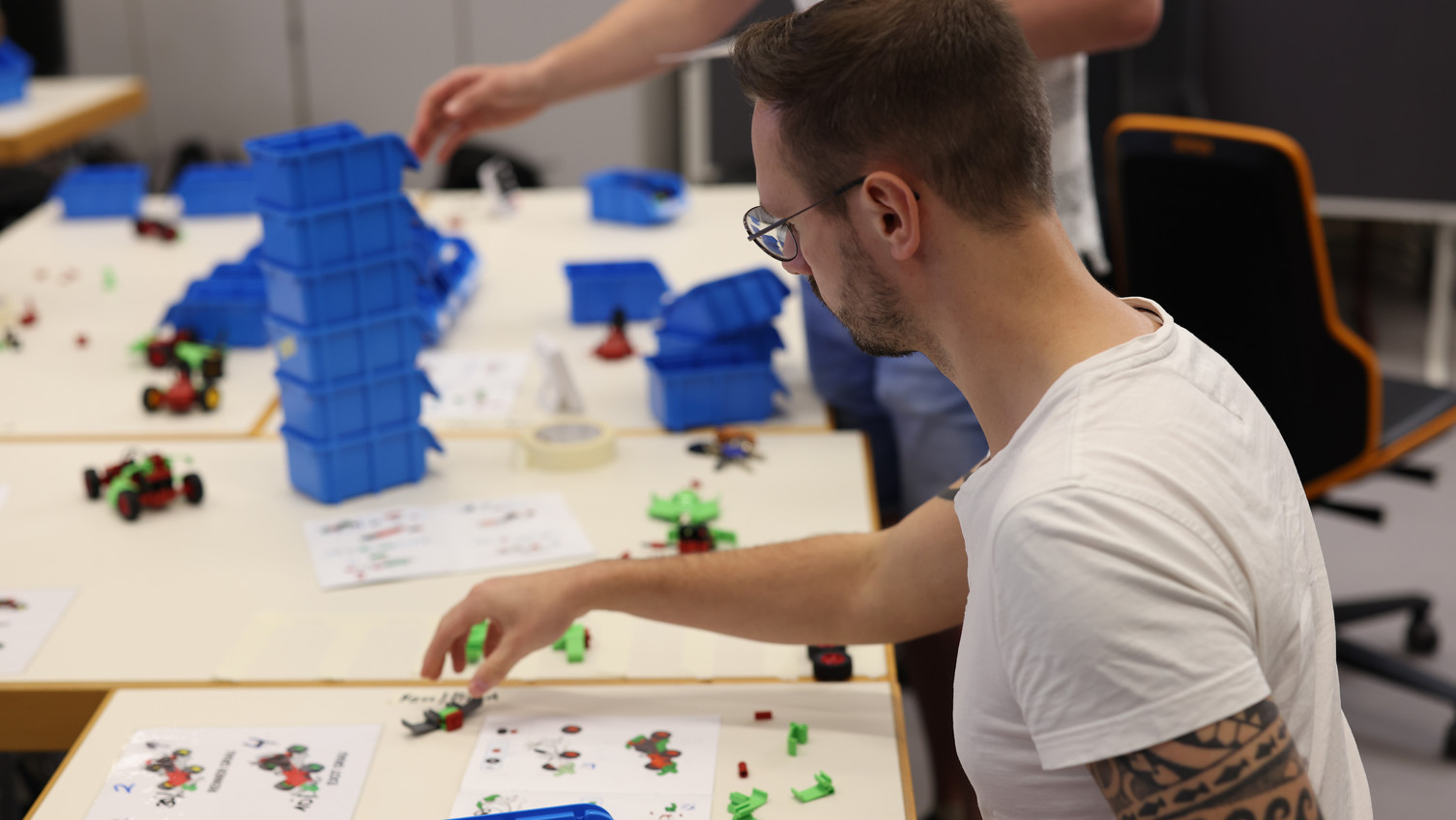

Based on scientific research, we develop innovative concepts for business models and circular production planning and actively support companies in their sustainable transformation. With the help of precise simulation environments, we test and validate these approaches in a practical and systematic manner for their effectiveness and transferability. The following aspects show the concrete added value this offers manufacturing companies.

Systematically anchoring sustainability requires new business models and a willingness to question established logics. Instead of relying on linear consumption and short-term product sales, the focus is on using, recycling and reusing products and materials for as long as possible.

The focus is on four central strategies:

- Closing loops (e.g. through reuse, remanufacturing, refurbishing and recycling),

- extending life cycles (e.g. through repair and maintenance),

- theintensification of use (e.g. through sharing or leasing),

- dematerialization through product-service systems, where customers no longer buy the product itself, but its functionality.

The transition to a circular business model requires changes on many levels:

- The value proposition is being redefined, for example through durable, modular or recyclable products and services that focus on functionality.

- Value creation and delivery is increasingly based on a circular model that promotes improved product design, optimized resource utilization, the reuse of used products and the development of long-term customer relationships.

- Value capture is increasingly based on adapted cost and revenue models such as usage or result-oriented billing, take-back premiums or cross-lifecycle contract models.

Circular business models offer companies the opportunity to strive for economic stability while at the same time conserving resources and creating new customer access. At the same time, their implementation places new demands on production processes and their modeling - and is therefore closely linked to circular production planning, resource planning and the design of traceable value creation systems.

Effective production planning and control is essential for manufacturing companies in order to be both logistically successful and sustainable. Circular strategies such as remanufacturing, refurbishment or repair characterize new production processes, which must also be taken into account in planning.

The return of used products creates complex material flows and places new demands on resource planning, capacity distribution and work organization. Today, production planning must take into account the fluctuating availability and quality of returns and their impact on employees, machines and delivery processes.

Transparent and adaptable planning processes are crucial in order to coordinate the combination of linear and circular processes in a meaningful way. They create the basis for economic stability and resource efficiency. Circular production planning not only enables shorter delivery times and higher margins, but also reduces raw material requirements and strengthens sustainability in industrial production.

The Leuphana Innovation Community Sustainable Production is committed to a climate-neutral, resource-efficient and economically viable transformation of manufacturing companies and brings together stakeholders from science, industry and society. Shape the future with us and become part of the community!