Student and Alumni experiences - Management & Engineering

On this page you find experiences of current and former students about the Masters Management & Engineering at Leuphana Graduate School.

Philip's experiences

31.08.2022 Philip Zander is about to complete his Masters degree. In the Management & Engineering programme, he has chosen the Production Engineering profile in order to build on his previous technical knowledge.

©Privat

©Privat

Why did you choose the Masters Management & Engineering?

In my Bachelor dissertation, I investigated an image-processing system as a replacement for conventional surface measurements in cooperation with an aviation company. In the process, the integration and further processing of digital information in the manufacturing process turned out to be a recurring requirement. With the Masters, I was able to start at this point, as the digitalisation of the holistic production process is a central component of the degree.

What did you study before your current Masters and where were you able to tie in with this study?

I also completed my Bachelor degree at Leuphana in the field of engineering with a focus on automation and production engineering. Due to its broad interpretation, I already had a good foundation in various technical areas, which I was able to build on in my Masters studies. New and challenging for me were the management contents as well as the quite extensive basics of programming. However, flexible and closely structured tutorials, a wide range of additional modules and a lively exchange between students and lecturers on an equal footing gave me enough opportunities to understand and internalise the new knowledge.

In your Masters programme, you have, among other things, the option to choose between two profiles and thus follow your own path. Which one did you choose?

Students of the Management & Engineering programme can choose between the profiles Production Systems and Production Engineering. I chose the latter because it is aimed at students with a technical undergraduate degree and in this way, I was able to deepen my previous knowledge from the Bachelor degree and expand it in a future-oriented way in the direction of Industry 4.0.

In your opinion, what is the ratio of management to engineering?

In the Production Engineering profile, about two-thirds of all courses have a connection to management or deal exclusively with it. The focus is clearly on understanding a technical/manufacturing company from the perspective of a manager. However, there are some intersections with engineering content, so that engineering also comes into play in a good two-thirds of all courses. Overall, I feel that both areas balance each other out.

Leuphana sees itself as an inter- and transdisciplinary university. How do you perceive this?

The concept of interdisciplinarity is already evident in the design of the Masters degree, in that economic approaches to a company are combined with technical knowledge. In addition, there is the possibility to bring another perspective, completely detached from one's own programme, into the study programme through Complementary Studies. Personally, however, I looked around in that one for courses that would allow me to delve into engineering and in this way complement my engineering-specific knowledge. The complementary studies programme also offered me this opportunity and, for example, I was able to further improve my ability in simulations of technical as well as non-technical control systems.

How do you like Lüneburg as a place to live? What should everyone have done in or around Lüneburg?

In contrast to some big cities, Lüneburg is not quite as hectic - nevertheless, it is a young, dynamic and worth seeing city. Especially in summer, I look forward to going for an ice cream on Am Sande from time to time or meeting up with friends on the Mensa lawn or in the city park. In any case, you should take a walk through the many side streets in the old town, it's like a little journey back in time.

What keeps you busy besides your studies?

During my studies, I worked as a student trainee in project management at an aviation company and was thus able to directly link a lot of the theoretical content of the Masters with practical experience. For a while, I did Shotokan Karate at the university sports centre and also took my 4th Kyu exam there. Apart from that, I also work on cars as a hobby, which gives me the opportunity to pursue my technical interests.

Do you already have an idea in which direction your Masters dissertation could go?

I am currently writing my Masters dissertation at the Helmholtz Centre Hereon on the subject of friction spot welding of different metals. I already had my first contact with the topic in the course research project and was also familiar with the process as a possible future alternative to riveting in aviation. It is all the more exciting to now be able to make my own research contribution to this.

What are your plans after the Masters?

After completing my Masters, I would like to go into industry and gain a professional foothold in a technology company. If it is possible, I could also consider resuming my work in the aviation industry, but I am not necessarily committed to that.

To whom would you recommend the Masters Management & Engineering?

All graduates of a Bachelor degree programme with a purely technical or economic-technical background who are interested in innovative manufacturing and business processes and their linking and implementation. If you envisage a professional future as a manager in technical companies or would also like to work in research and development, this Masters is the right choice for you. But the Management Studies module also provides students with the right tools for taking the step into entrepreneurial independence, so that in my opinion there are broad career prospects after completing this Masters degree.

Interviewer: Jonas Kernein

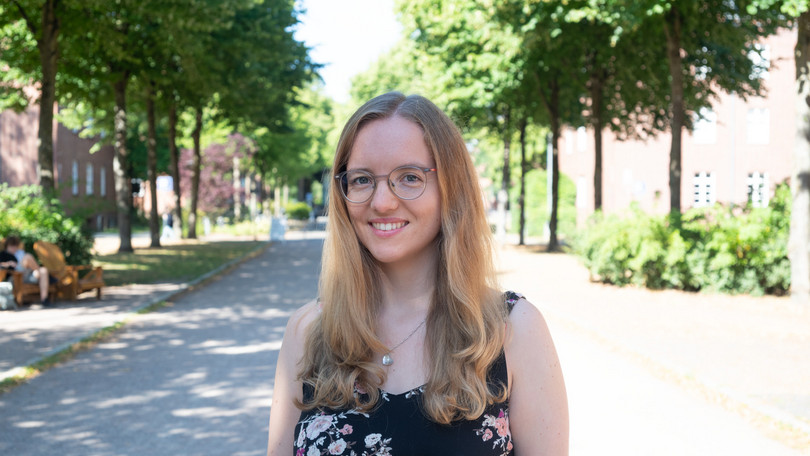

Gillian's experiences

24.08.2022 Marie Gillian Guerne found her way to engineering through her interest in sustainability issues. After a semester abroad in Almería, Spain, she is now planning her Masters dissertation in Blue Engineering - and will soon be giving a seminar on the subject.

©Anastasia Adasheva/Leuphana

©Anastasia Adasheva/Leuphana

Why did you choose the Master Management & Engineering?

I became aware of the Masters programme in Management & Engineering through a few detours. I also completed my Bachelor degree at Leuphana. Due to a semester abroad in Ecuador as well as a voluntary internship, my studies were prolonged and the chair of logistics, whose focus I had chosen, dissolved while I was abroad. After my return, it was therefore difficult to find a supervisor for my Bachelor thesis. In a module of the complementary studies, which is based in engineering, I finally found an exciting topic and intensively dealt with the business model of makerspaces and engineering in my last semester of my Bachelor degree. Through the Complementary Studies module as well as my Bachelor thesis, I had my first points of contact with engineering. My original plan was to deepen my knowledge of Sustainability Science in the Masters programme. In the end, however, I was convinced by the Masters in Management & Engineering, as it allowed me to supplement my knowledge of business administration and sustainability with that of engineering. A big motivation was to later be able to develop solutions for sustainability problems using technical approaches.

What did you study before your current Masters and where could you tie in with this study?

I completed my Bachelor with a major in business administration and a focus on logistics and a minor in sustainability science, also at Leuphana. Thanks to the focus on logistics, I was able to pick up on a number of points in my Masters degree. Among other things, a voluntary internship that I completed during my Bachelor degree at a large German technology company in the area of logistics also helped. The basics of engineering were particularly new, but they were explained to us from the ground up in the focus area "Production Systems".

In your Masters programme you have, among other things, the option to choose between two profiles and thus follow your own path. What did you choose and how do the profiles differ from each other?

The Masters Management & Engineering has two profiles: "Production Systems" and "Production Technology". Since the "Production Technology" profile is already aimed at students who have already studied engineering in the Bachelor programme, I was pre-determined to choose the "Production Systems" profile. I think the division into the profiles makes a lot of sense, because for me, for example, the basics were very important. In the further course of the Masters degree, I had the opportunity to select various modules and choose a path.

You also have the option of taking an additional 20 CP in the Masters programme. I used these in the first semesters to take modules from the Masters programme in Sustainability Science and to pursue my interest in the area of sustainability here as well.

What is the ratio of management to engineering in your opinion?

We take a total of three modules from the field of management, one in each of the first three semesters. These are very large lectures, as all Management Masters attend together. Here we learned about organisations, strategies, innovations, digitalisation and entrepreneurship. However, I would say that there are also management components in the engineering part of the Masters programme. In modules such as production management or production logistics, more specific knowledge is taught. In addition, we can take subjects from other masters in addition or as elective modules, and so I learned something about the management of start-ups, for example.

You are currently doing a semester abroad: Which place did you choose and what were your reasons for doing so? Can you give us a brief insight?

I also wanted to integrate a semester abroad into my Masters. Unfortunately, due to the Corona pandemic, it wasn't as easy as it was for the Bachelor. Originally, I decided to stay in Taiwan in the first semester because there were some exciting modules on environmental engineering there. However, after this was cancelled twice due to Covid, I came up with a plan B in my third application and finally completed my semester abroad in Almería (Spain) as a free mover. Almería turned out to be the perfect alternative. The city is located directly on the coast, about 30 minutes away is the Cabo de Gata Nature Park with its beautiful beaches, about 20 minutes inland is the only desert in Europe, and in winter I was able to go skiing in the Sierra Nevada, about 1.5 hours away. The university sports programme at the Universidad de Almería had a lot of good offers. There was everything from kayaking to climbing, canyoning, hiking, diving and skiing. The Erasmus Student Network also organised an excursion almost every weekend, so I could always choose. The engineering courses were very demanding, as everything was taught in Spanish and each subject always required more than three exams. Next time, I would make sure that the courses are offered in English. Basically, I can highly recommend a stay abroad to everyone.

Leuphana sees itself as an inter- and transdisciplinary university. How do you perceive this?

I perceive inter- and transdisciplinarity strongly at the university and in my degree programme. Especially in my focus area, we are very interdisciplinary because no one has studied engineering before. For example, we are students with backgrounds in business administration, environmental sciences, medical technology or logistics management. At the moment, it is also very impressive to see how diverse the topics of the Masters dissertations have been chosen (e.g. circular economy, logistics management, medical technology, production management, subject didactics).

How do you like Lüneburg as a place to live? What should everyone have done in or around Lüneburg?

I like Lüneburg very much as a place to live. I especially like the fact that everything is within 15 minutes cycling distance. Lüneburg's old town and the Kurpark are beautiful, as are the campus and the central building.

Everyone should definitely have taken a canoe tour on the Ilmenau and visited lunatic Festival. Lüneburg is also a great place to go on bike tours. For those who need a little city life in between, Hamburg can be reached quickly by train.

What keeps you busy besides your studies?

There are many things to do in Lüneburg besides studying. Leuphana has a good range of initiatives and I have been involved in various initiatives since my first semester. Right at the beginning of my studies, I started to get involved with the association Enactus Lüneburg e.V., a social entrepreneurship initiative where we work on various projects. My first project, for example, was the adaptation and introduction of an organic box model on campus. At the moment, we are working on a city tour of Lüneburg from the perspective of blind and visually impaired people to create more awareness for this topic. Since I started my Masters, I have also been active in the WINGS student council. In addition, I have found part-time jobs as a student assistant almost continuously since my Bachelor degree. The University Sports at Leuphana also has many offers.

Do you already have an idea of the direction your Masters dissertation might take?

My Masters dissertation will be about the intersection between engineering and sustainability. The analysis of a categorisation of 3570 conference articles revealed that the topic of sustainability is insufficiently addressed in engineering education. Which is why I will be offering a seminar on blue engineering next semester together with Dr Block. The basic idea of the module is to sensitise students and strengthen their awareness of the responsibility of the engineering profession in order to develop socially and ecologically compatible technologies.

What are your plans after the Masters programme?

So far, I don't have any concrete plans after the Masters programme. I can definitely imagine an academic career, but I would like to work in the private sector for a few years beforehand to gain experience. Thematically, I would ideally like to find a job that combines sustainability with engineering.

To whom would you recommend the Masters Management & Engineering?

From the perspective of the "Production Systems" profile, I can recommend the degree programme to all students with a basic interest in engineering. Previous knowledge is not required. This programme is one of the few in Germany that makes it possible to complete a Masters degree in this field without prior knowledge.

Interviewer: Jonas Kernein

Danial's experiences

15.07.2022 Danial Mousavi has followed his enthusiasm for technology and chosen the Masters programme Management & Engineering at Leuphana Graduate School. Among other things, he is interested in the use of artificial intelligence in supply chain risk management - and is toying with the idea of completing a doctorate.

©Anastasia Adasheva/Leuphana

©Anastasia Adasheva/Leuphana

Why did you choose the Masters Management & Engineering?

I had already completed a commercial apprenticeship prior to my studies and during my engineering studies I was very interested in the economic modules in addition to the technical ones. The internationally oriented Masters in Management & Engineering promises an in-depth interface between the two fields of technology and business. Combined with modules such as Machine Learning & Data Mining or Numerical Methods, which complement the Masters with programming-heavy content, the programme is a well-rounded package for a modern engineering degree. That's what made me choose this programme.

What did you study before your current Masters and where could you tie in with this study?

I also completed my Bachelor degree in engineering at Leuphana. Accordingly, it was relatively easy for me to tie in with my current studies, as many of the foundations for most of the modules were already laid in my Bachelor studies. Especially modules such as Production Management or Logistics and Materials & Engineering deepen content from the Bachelor programme. In addition, several group projects take place in the Masters programme, which in turn promotes cooperation and interaction between students and brings you closer to your future professional life.

In your Masters programme, you have the opportunity to choose between two profiles and thus pursue your own path. Which one did you choose?

At the beginning of my Masters programme, I had the choice between the profiles Production Systems and Production Engineering. I chose the Production Engineering profile because this profile is designed for students with a technical Bachelor degree. This enables me to further deepen my prior technical knowledge. Although the complementary studies offer students the chance to deal with topics from other degree programmes, there are also some interesting engineering modules in this framework that usefully complement the contents of the Masters degree. Through the electives, there is also the opportunity in the third semester to gain an insight into another management degree programme.

In your opinion, what is the ratio of management to engineering?

The programme offers a total of three management modules. At first glance, that sounds like a small number. In my opinion, this is nevertheless okay, since most of the engineering modules have a clear connection to management. Moreover, the Masters programme with the profile Production Engineering is still a technical programme, which in my opinion justifies the small number of management modules.

In your opinion, how is your programme positioned in terms of internationality?

In my opinion, the programme is quite international. All management modules and individual engineering and complementary modules are taught in English. In addition, students of the programme have the opportunity to spend a semester abroad. As far as I have noticed, this is a good option in the third semester of the Masters programme. Some of the partner universities are in Brazil, the USA, Italy, Japan and China.

What is the relationship like among the students and with the lecturers?

Despite Corona in the first semester of the Masters programme, I had the feeling that the relationship among the students and with the lecturers is very good. The students also like to do things together outside of the university. The lecturers are very committed and respond to questions or other needs of the students. In my opinion, this is mainly due to the fact that the Management & Engineering programme is relatively small, except for the management modules. In the second semester, all courses are now held in attendance and my initial feeling has been more than confirmed.

What keeps you busy besides your studies?

In addition to my studies, I am also a student assistant in the Production Management working group at the Institute for Product and Process Innovation (PPI) at Leuphana. There I support two of Prof. Matthias Schmidt's research assistants with various tasks. In my free time, I regularly go to the gym or do something with my friends.

Do you already have an idea of what direction your Masters dissertation might take?

I don't have a concrete idea yet. However, I would like to start with the topic of my Bachelor dissertation. Here I conducted a systematic literature analysis on the use of artificial intelligence in supply chain risk management. The dissertation was therefore very theoretical. Accordingly, I would prefer to have the opportunity to include practical aspects in addition to theory in my Masters dissertation.

What are your plans after the Masters programme?

I haven't decided exactly yet. Currently, I'm toying with the idea of doing a doctoral programme after my Masters before going into the private sector - preferably in a management consultancy. I also find it interesting to teach as a lecturer at a university in addition to my professional activities.

To whom would you recommend the Masters in Management & Engineering?

I would recommend the programme primarily to people who are enthusiastic about technology, who enjoy solution-oriented thinking and who want to look at the big picture at a production company. Mathematical and logical thinking skills are certainly an advantage here. The possibility to choose between the two profiles Production Engineering and Production Systems makes the degree programme suitable for both students with and without a technical background. I also think that the degree programme can be very interesting for students who want to do a doctorate after the Masters degree, as the professors place a lot of emphasis on scientific work and students are both encouraged and challenged in this regard.

Interviewer: Jonas Kernein

Katharina's experiences

16.12.19 Katharina Wolff shares her experiences from her Masters studies in Management & Engineering at Leuphana Graduate School.

©Leuphana

©Leuphana

"Cars are no longer just red, green or blue," explains Katharina Wolff. This is precisely what makes the field of production technology exciting for the 22-year-old student. "It's not only materials and machines that play a role in a production hall. Due to ever-increasing individuality in many areas, the workflows and processes in a factory in particular need to be better planned." In order to meet these current challenges, Katharina Wolff decided to study the Masters in Management & Engineering at Leuphana Graduate School. "I looked at many universities. But Professor Schmidt's focus at Leuphana particularly convinced me." Matthias Schmidt is a professor of production management and has, among other things, created the Digital Factory. Students can use the model there to learn how production processes can be accelerated, for example through better networking of work steps. Katharina Wolff works part-time alongside her studies at a large medium-sized company for drive and automation technology in Aerzen near Hameln and can put what she has learned into practice: "There I am also involved in planning improved production processes."

Studying abroad in Shanghai

Even at school, Katharina Wolff was very good at mathematics: "I was equally interested in engineering and economics." So studying industrial engineering was an obvious choice. She completed a dual Bachelors degree in industrial engineering with a focus on production technology at a University of Applied Sciences. Even then, Katharina Wolff was working at the company in Aerzen. She would also like to write her Masters dissertation here: "There is a cooperation with Leuphana. Professor Schmidt does research on production management there." The North Rhine-Westphalian can also imagine doing a doctorate: "Especially in view of this, it is helpful that some course content is already taught in English, the language of science." Immediately after graduation, however, Katharina Wolff would first like to immerse herself more deeply in practice and would like to continue working for her current employer. But she can also imagine a career abroad: "I was already in Shanghai on a secondment from my employer during my studies."

Author: Dr. Marietta Hülsmann

Vanessa's experiences

20.03.17 Vanessa Hacke shares her experiences from her Masters studies in Management & Engineering at Leuphana Graduate School.

©Leuphana

©Leuphana

What did you do before you applied here for the Masters Management & Engineering?

I did a dual study programme at Volkswagen, for which I studied in Wolfenbüttel and completed my Bachelors degree in industrial engineering with a focus on mechanical engineering. In the first part, I did an apprenticeship as an industrial mechanic. That was during the semester break, we had two practical semesters. So I know a bit about machining processes and assembly. And in the second part, I worked in the planning department for press tools. After that I went abroad for a year, worked for VW in Mexico and was responsible for just-in-sequence parts in logistics.

What appealed to you about the Masters in Management & Engineering here at Leuphana?

I wanted to continue studying industrial engineering with these two areas. In other words, I didn't just want to go down the technical track and not just the economic track either. That's why I chose Management & Engineering, because it combines both.

Since this semester, there are two specialisations in the study programme: Production Systems and Production Engineering. - What do you mean by that? Is it about how assembly line production works?

Before that, of course, we have the whole supply chain, the whole value chain: it starts with the supplier, then goes through your own factory, all the way to the customer - how I link all that is what production management is about. It's also about delivering parts 'just in time', for example: these then go directly to the production line, i.e. are installed directly. Or 'what do I do when there are bottlenecks?' 'How do I order my suppliers?' 'How do I proceed?' 'Which ones do I choose?' So it's actually... everything is complete.

So production engineering is the management needed to produce and distribute products in quantity, right?

Yes. But of course I also need technical background knowledge, I also have production engineering, where I learn how things are welded, or which techniques I use for which materials - so it's not only this economic background and how I organise my production, but also that I have an idea of which factors from manufacturing play into the production strand. That is the good thing about industrial engineers, that they have this technical background, but also the economic thinking. They can combine both and work at interfaces such as logistics, production planning, technical purchasing or sales - that's where industrial engineers are really in demand.

How do you rate the management studies in your degree programme?

We just had organisation, strategy and innovation - and that's exactly what I wanted - which is what industrial engineering is all about: I also learn a strategic way of thinking, recognise what I have to do when I want to introduce a new strategy, what should my organisation look like, with which types of organisation can I achieve which goals and how do I implement innovation? That's exactly what I can implement later in my job - and probably even better because of my mechanical engineering background. That's why I find Management Studies really fitting. Working in press shop planning gave me direct insight: my colleagues there always sat in simultaneous engineering teams, which means that colleagues from different areas meet to parallelise this engineering or product planning process as much as possible and to keep the whole time process as short as possible.

Interviewer: Ina Seifert

Martin's experiences

28.09.20 The engineer was the first doctoral student at Leuphana to graduate with the newly introduced degree of Dr.-Ing. During his doctorate, he developed an innovative manufacturing process in the field of 3D printing to produce metallic structures.

©Leuphana

©Leuphana

Even when he was still at school, Martin Frönd knew how beneficial technical understanding is: the engineer grew up in Lower Saxony's Wendland region. Whenever his moped was broken, he had to fix it - or walk. "I would often repair it together with my father," the 29-year-old recalls. It was this kind of sense of achievement, of solving problems in an application-oriented manner, which shaped his choice of career: "In physics and mathematics, there is always only one solution behind an equation. Clear answers suit me." In 2011 he therefore applied to study engineering sciences at Leuphana. The programme fulfilled his expectations, while also being challenging: "But I enjoyed the content so much that I passed the exams quite well," remembers Martin Frönd. Back then, the student did not yet see himself in research: "Good preparation for employment in an industrial production company was important to me. Since I believe that this also includes a strong awareness of the sustainable design of successful business processes, I chose business studies as a minor".

His plans to enter industry quickly changed for the time being when he took up his subsequent Master's programme in "Management and Engineering": Dr.-Ing. Benjamin Klusemann, Professor of Local Engineering, in particular Process Simulation and holder of a shared professorship with the Helmholtz Centre Geesthacht (HZG), had just been appointed to Leuphana. Martin Frönd was extremely interested in his lecture: "Professor Klusemann went very deeply into the technical background, but was able to convey it very clearly". The student asked whether he could write his Master's thesis with the scientist. Benjamin Klusemann agreed, provided the student's module grade was good enough - it was. Benjamin Klusemann is also head of department at the Institute for Materials Research at the HZG, where he invited Martin Frönd for an interview for an experimental thesis. "Cooperation with the HZG is a great asset to Leuphana's research activities. I was able to work there independently with an industrial high-power laser during my master's thesis, and I was also able to examine the processed titanium components in very well-equipped laboratories. Laser beam welding is a common procedure in modern manufacturing technology, as it is a fast and effective process that can be easily automated. However, high residual stress values and component deformations often occur during the laser welding process, and these should be experimentally investigated and reduced as part of my master's thesis," explains Martin Frönd.

In his doctoral thesis he dealt with laser material processing of aluminium. "A material that is of great industrial interest, but also poses major processing challenges," Martin Frönd describes. "The research question of my doctoral thesis was motivated by the fact that although laser-based 3D printing of aluminium seemed very attractive from an industrial point of view, this material has an immense laser beam reflection of more than 95 percent. This meant that laser-based 3D printing of large aluminium structures was hardly feasible, either technically or economically". It was a problem that the young scientist solved in an application-oriented way in his doctoral thesis, as a result of which he received research prizes for two of his publications from Leuphana University. "At the beginning of the doctorate, a joke prevailed among the doctoral students: For every letter of the Dr.-Ing. you need one year. But the supervision was excellent and the support from family, partner and friends as well, so that I was able to complete my doctorate much earlier," reflects the former research assistant gratefully. He published several scientific articles and submitted his dissertation after just less than three years. Martin Frönd is thus the first doctoral student at Leuphana to graduate with a Dr.-Ing. in engineering sciences. The title is only awarded in Germany and is regarded worldwide as a trademark for German engineering. Martin Frönd is proud of his Dr.-Ing. degree: "We are engineers. That may also be mentioned in the title."

The job of his dreams followed swiftly: "Today, I work as deputy quality manager for an internationally established tapered roller bearing manufacturer. The transition to the industry was smooth and I enjoy the daily tasks immensely. Everything I learned in my studies and doctorate comes together here: With my team, I analyse different problems every day and develop effective technical solutions. In addition, at some points interdisciplinary skills are required to evaluate existing structures and adapt them if necessary. Especially when working in science, I have learned to think innovatively and to abandon the status quo when it is no longer sufficient. The management studies at Leuphana have also given me a very good foundation for dealing with strategic issues," Martin Frönd describes.

Author: Dr. Marietta Hülsmann

Contact and Counselling

First contact point

The Information Office (Infoportal) is your contact point for

- general information on the application procedure

- initial questions about the study programmes offered at Leuphana

- making an appointment with the Graduate School Student Counselling Service.

Information Office

Building 8, Ground Level

Fon +49.4131.677-2277

studierendenservice@leuphana.de

Campus opening hours

Mon - Thu 9.00 am - 4:00 pm

Fr 9.00 am - 12 noon

Student Counselling

To make an appointment with our Student Counselling Service, please use our booking tool on our website.